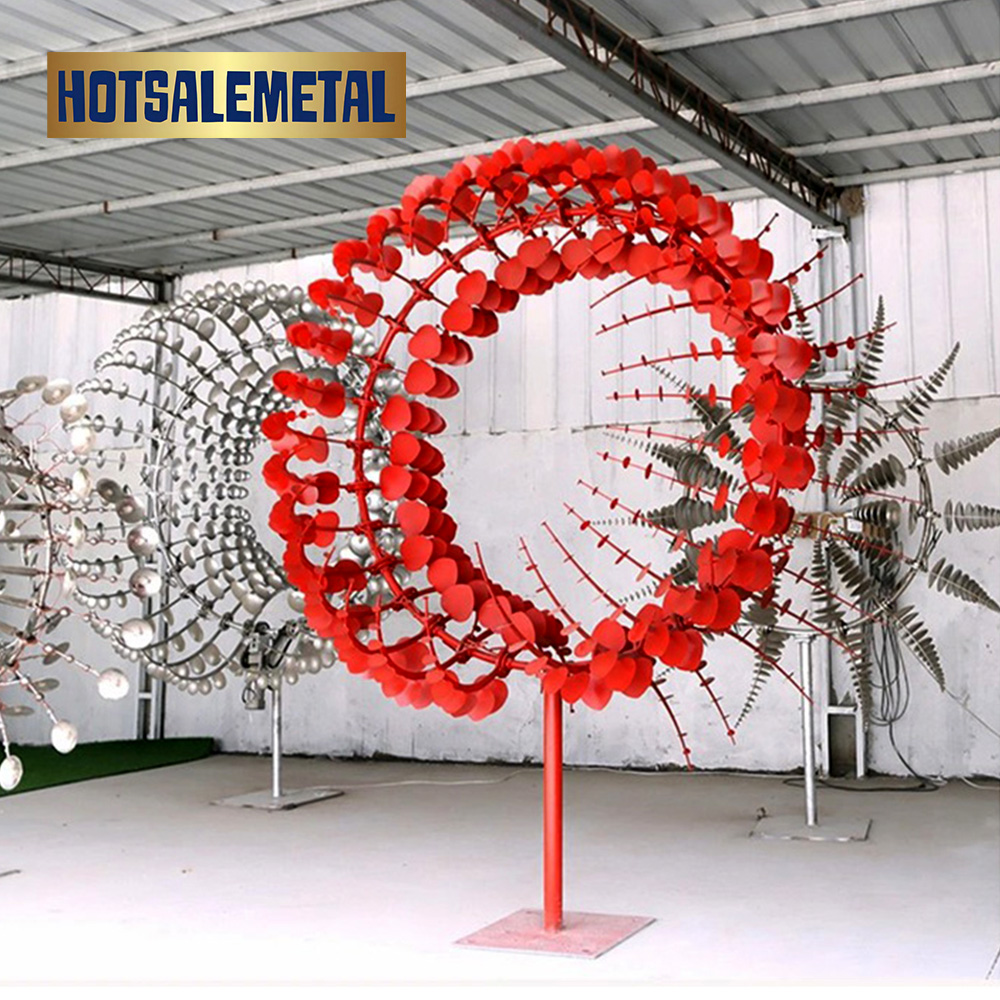

From design to installation: One-stop stainless steel sculpture services make art a breeze.

With accelerating urbanization, stainless steel sculptures, with their modern appeal, corrosion resistance, and easy maintenance, are becoming a popular choice for urban landscapes, commercial spaces, and public art. However, for many businesses, scenic spots, and individuals, customizing stainless steel sculptures often presents challenges such as cumbersome processes, high communication costs, and inconsistent quality. How can artistic creativity be efficiently realized? One-stop stainless steel sculpture services offer the perfect answer—from design to installation, worry-free and effortless!

I. Are you facing the challenges of traditional sculpture customization?

Design communication gaps: Designers and manufacturers are disconnected, and repeated revisions to the plan can still fail to achieve the desired results.

Risk of project delays: Phased outsourcing can lead to delays due to poor coordination, impacting project delivery.

Quality control blind spots: A lack of standardized materials, craftsmanship, and installation can significantly reduce the quality of the finished product.

II. One-stop service: How to overcome customization challenges?

1. Professional Design Team, Accurately Reflecting Creative Concepts

Experienced sculptors and structural engineers collaborate to comprehensively consider everything from artistic aesthetics to mechanical stability.

We provide 3D modeling and rendering preview services, allowing for direct production upon confirmation, eliminating the need for “paper work.”

We support personalized customization, tailoring designs for abstract art, corporate IP, and cultural landmarks.

2. Standardized Production Process, Controllable and Traceable Quality

Using high-quality 304/316L stainless steel to ensure weather resistance and safety.

Incorporating precision equipment such as laser cutting and CNC bending, we ensure meticulous detailing comparable to works of art.

Strict quality inspections are implemented throughout each process, providing real-time feedback on production progress and enabling remote customer monitoring.